At present, as a major global producer of household appliances, China's production scale is continuously expanding, resulting in a huge demand for bulk raw materials in the household appliance industry. According to data from the China Household Electrical Appliances Association, in 2007, the amount of steel used in major household appliances exceeded 5.7 million tons, and the amount of non-ferrous metals and engineering plastics used exceeded 1 million tons each. The processing of a large number of metal and plastic components used in household appliances requires a huge demand for machine tools and molds.

The large number of board and sheet components used in household appliances have special requirements for the machine tool industry, namely large quantity and high speed.

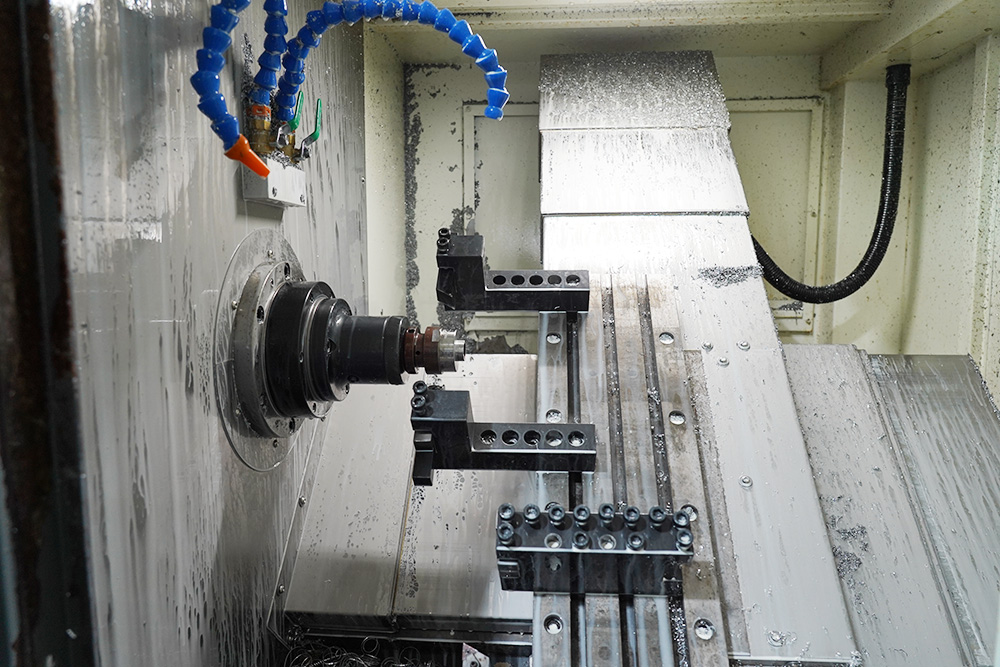

Various CNC punching machines are one of the important machine tools for processing in the household appliance industry. At present, many users tend to use CNC composite punching and shearing machines (which can form CNC punching and shearing composite flexible processing lines), but the market for single CNC punching machines is still very large, mainly used for processing plate punching parts with various sizes and specifications of hole patterns. It has a wide market in the large electrical control cabinet processing industry and can also be used for processing other large quantities of plate punching parts.

The CNC punching and shearing composite machine can complete punching, forming, and shearing of sheet metal in one go, especially suitable for processing sheet metal with subsequent bending processes. Multiple processes share a set of CNC system, hydraulic system, and feeding robot arm. Compared with the single machine connection of CNC punching and angle shearing machine, it can not only reduce equipment investment, save floor space, and reduce failure rate, but also serve as a host to form a punching and shearing composite flexible machining line.

Household appliances widely use various small electronic components. The processing demand for these small electronic components has promoted the development of high-precision and high-efficiency high-speed presses. China Jinfeng, Jiangsu Yangduan, Gaojiang Precision Machinery, Jiangsu Yangli, Xuduan, and Xi'an Tongli all have high-speed press products. These presses are widely used in the electronics and microelectronics industries, comprehensively improving the industry's technological equipment level and replacing a large number of imported machine tools.

Laser cutting machine is also one of the important machine tools for processing electrical components. It does not require molds and can replace stamping processing in the production of small batches and complex parts, with lower operating costs than CNC punching machines. The representative domestic production enterprise is Jinan Jiemai CNC Company.

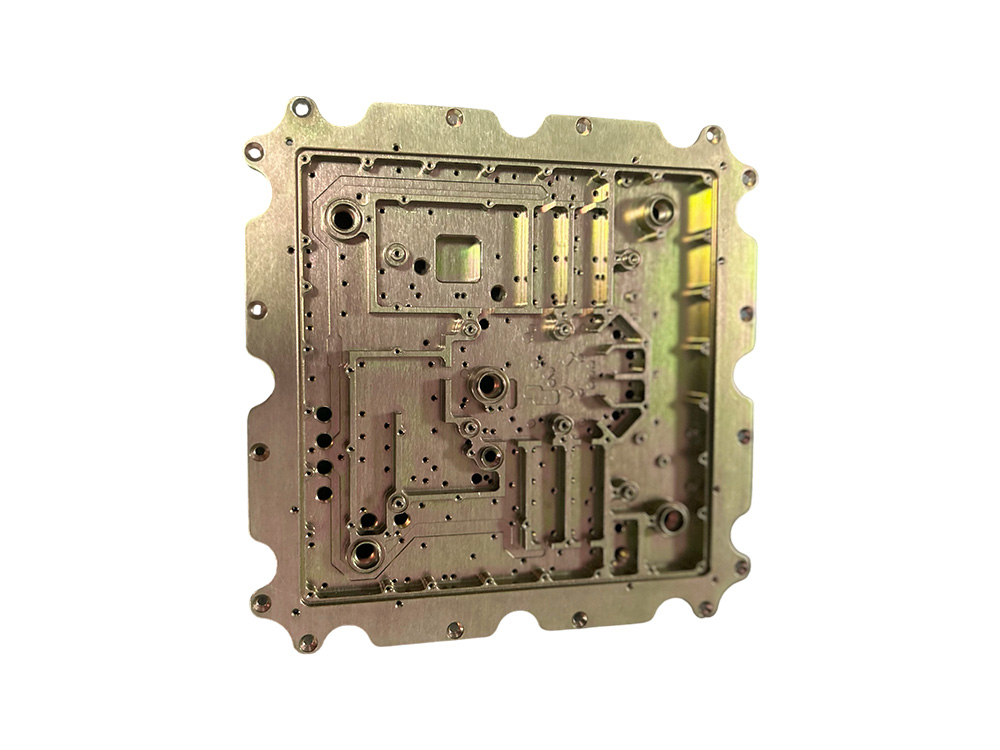

The home appliance industry not only requires various processing machines and stamping molds, but also a large number of plastic parts that need corresponding injection molds to match them. For example, a refrigerator requires about 350 sets of molds; A fully automatic washing machine requires approximately 200 sets of molds; A single air conditioner only requires about 20 sets of plastic molds; A single color TV requires approximately 140 sets of molds, and the market for color TV molds alone is about 2.8 billion yuan per year. With the fierce competition in the home appliance market, shell design has become an important part, which puts forward new requirements for the color, feel, accuracy, wall thickness, etc. of home appliance shells, and there is a great demand for new molds. The rapid development of the mold industry also drives the demand for various machining centers and advanced machining machines.

Message successfully sent