The wide variety, high quality, and innovative highlights of die-casting molds, low-pressure casting molds, and gravity casting molds have surpassed the past, reflecting the trend of China's casting mold manufacturing towards large-scale, complex, rational structural design, and humanized development in recent years. Each enterprise keeps up with the new trends of foreign counterparts and strives to narrow the gap between China and advanced industrial countries abroad. Among them, as the largest domestic commodity casting mold manufacturing base, the Beilun and Xiangshan regions of Ningbo have a large number of exhibitors, demonstrating the strong advantages and strength of the "hometown of Chinese die-casting molds" and "hometown of Chinese casting molds".

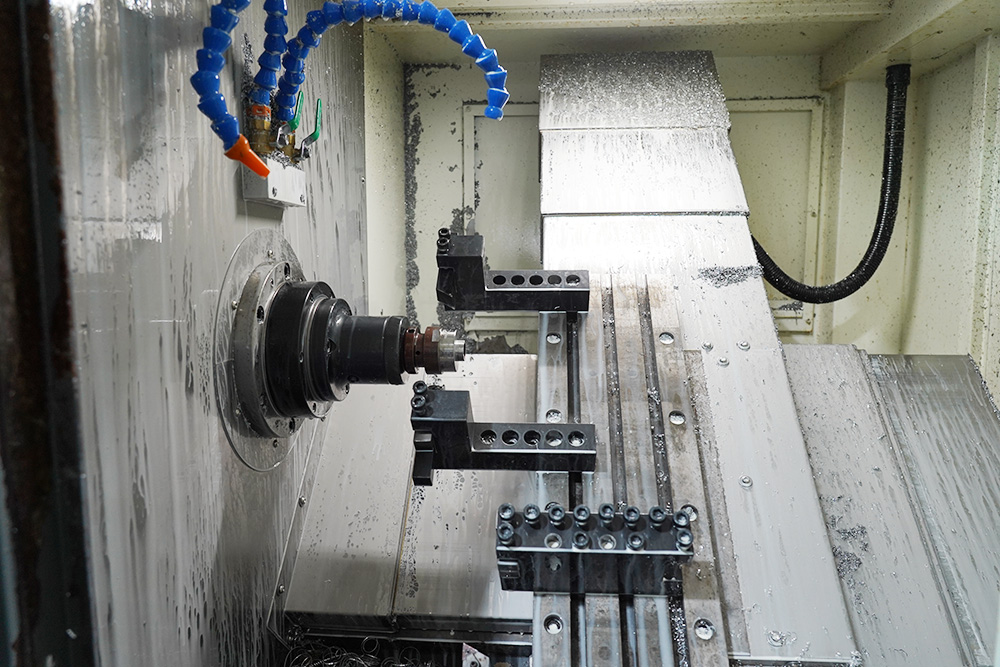

The trend towards large-scale casting molds is evident. With the rapid increase in the number of large tonnage die-casting machines in China's die-casting industry, the demand for large die-casting molds is becoming increasingly urgent. The inability to match the corresponding molds domestically has been hindering the synchronous development of the die-casting industry. In recent years, many mold companies have improved their design and manufacturing capabilities by purchasing large-scale processing and heat treatment equipment through technological transformation, which has initially alleviated this situation. The 53 ton "Automobile Engine V6 Cylinder Block Die Casting Mold" exhibited by Ningbo Beilun Huiwang Mold Industry Co., Ltd., and the 50 ton "Engine Transmission Intermediate Housing" Die Casting Mold exhibited by Ningbo Zhenzhi Machinery Mold Co., Ltd. and Ningbo Beilun Huiwang Mold Industry Co., Ltd. are all super large die casting molds installed on 38000N-40000N large die casting machines. The mold weighs 20-30 tons, and die-casting molds for automatic transmission housings, cylinder bodies, elevator pedals, and large heavy-duty truck transmissions have also appeared at multiple exhibition booths. In addition, the large cast iron diesel cylinder body produced by the "4114 cylinder body mold" exhibited at Hangzhou Heli Machinery Co., Ltd. has a large volume and complex shape. This indicates that China has made significant progress in the ability and level of manufacturing large casting molds, and the localization rate of large casting molds has been improved.

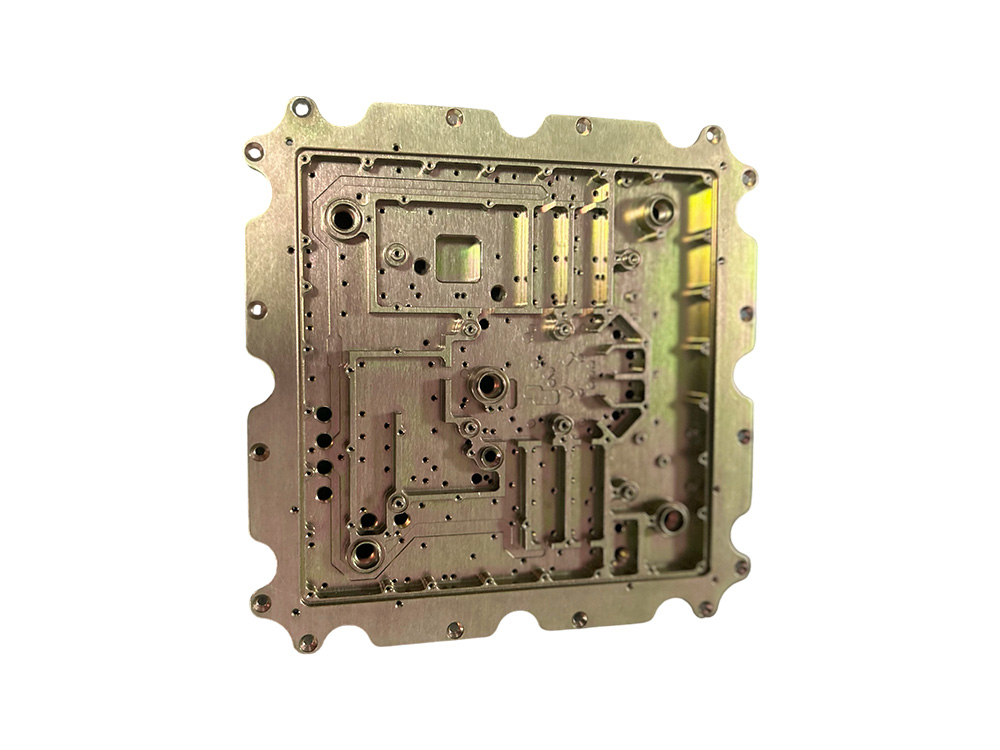

The complexity of castings makes mold manufacturing increasingly difficult. Due to the lightweight requirements and increased functionality of castings, the shape of castings has become increasingly complex, and the requirements for dimensional accuracy and internal and external quality have become more stringent, which puts higher demands on the production of molds. Several high-level molds at this mold exhibition attracted attention. For example, the heavy-duty truck engine part "Cummins large gear chamber die-casting mold" of Guangzhou Mold Manufacturing Co., Ltd. is composed of 2400 parts, with 5 sliding blocks pulled out by oil cylinders around, guided by three square guide columns, and positioned by four precision positioning elements to ensure casting accuracy. To meet the internal quality requirements of the product, the die-casting process adopts vacuum die-casting and extrusion pin technology inside the mold. By adopting a finger shaped flow channel design scheme, the metal liquid can flow in its own way, which can effectively control the flow direction, flow rate, and velocity of the metal liquid and improve product quality. The mold used large moving blocks to assist in molding, designed a complex temperature control system reasonably, arranged 40 cooling routes, 25 water separators, and more than 800 temperature control components; At the same time, 21 temperature monitoring points are arranged on the mold, and an external temperature value digital display is connected. Based on real-time temperature monitoring feedback, parameters are input at the control end of the die-casting machine to achieve program control of the start, end, and length of cooling time, thereby ensuring good temperature control capability during mold operation. The "X90 steering gear housing" die-casting die produced by Ningbo Xinda Mould Manufacturing Co., Ltd. is a long barrel shaped product, which needs to be drawn in several different directions. It requires two cavities for one the first mock examination. The company has solved the problems of mold separation selection, cooling of slender cores and repeated positioning. Now it has produced a series of steering gear housing die-casting dies and exported many sets to Europe. The "1.8T Engine Cylinder Block Mold" presented by Ningbo Heli Casting Mold Technology Co., Ltd. is used to produce the 1.8TS automotive engine cylinder block for Guangzhou Automobile Group. It adopts a variable cross-section pouring system and a special core support and head structure in the mold structure to solve the deformation of the cold core thin wall water jacket during the pouring process. It is a successful casting mold that contributes to the development of domestic independent brand automobiles. The die-casting parts of the "rack housing" and "gearbox" displayed by Ningbo Shengji Machinery Co., Ltd. reflect the company's attention to detail in the mold making process, exquisite craftsmanship, high dimensional accuracy, and clear and beautiful appearance.

The large-scale die-casting mold for V-shaped automobile cylinder body has been introduced. As the "heart" of automobile manufacturing - the cylinder body die-casting mold for engines, its research and development and manufacturing are extremely difficult, with extremely high technical content and strict product technical quality indicators. It has always been a challenge that die-casting mold manufacturers are committed to overcoming. The "Automotive Straight Four Cylinder Die Casting Mold" made its debut at the previous mold exhibition, attracting attention in the industry. After two years, 7-8 domestic manufacturers have been able to manufacture it. The "Automotive Engine V6 Cylinder Die Casting Mold" exhibited by Ningbo Beilun Huiwang Mold Industry Co., Ltd. has once again caused a sensation in the industry. This mold is the first domestically developed V-shaped cylinder die casting mold, and there are few manufacturers who have produced similar molds abroad. The casting is 530mm× 360mm× 300mm, The mold has a large external dimension (1935mm× 1850mm× 1690mm), a mold weight of 53T, and is difficult to process and assemble. The product has multiple external features and requires a large number of sliders. The castings also have high requirements for density and die-casting yield, making it a large, complex, and difficult die-casting mold. The mold adopts a double-sided feeding sprue, and each major slider adopts dual oil cylinder pulling, special slider friction pair, and rear positioning structure to ensure smooth and reliable operation. Due to the large heat capacity of castings and poor temperature balance conditions for mold operation, it is necessary to strengthen the control of mold operation temperature through multiple measures.

Technological progress has improved the overall level of the industry. The application of CAE has returned from being solely for the purpose of winning orders to playing its practical technical role, from customer requirements to becoming an essential auxiliary tool for designers. Many of these enterprises have also established their own database of mold infrastructure, standard parts, casting machine models, casting process parameters, etc., which facilitates engineers to select typical cases and use parameterization methods to achieve resource sharing during design, shortening the design cycle. In addition, when undertaking molds, enterprises are more concerned with transitioning from "whether they can produce" to "whether they can do well", and the concept of "winning by quality" is strengthened, focusing on extending the service life, ensuring reliability and stability, improving the pass rate of finished products, and production efficiency. Pay attention to the monitoring, feedback, and automatic adjustment of various parameters during mold operation, making the mold more user-friendly and intelligent. For technological and structural innovations and inventions, the enthusiasm of enterprises to apply for national patents is high, and the awareness of intellectual property protection is significantly enhanced.

Message successfully sent