The high strength and hardness characteristics of zinc alloys make them an ideal substitute for mechanical processing, pressing, stamping, and assembly parts. Compared with aluminum die-casting alloys, zinc alloys exhibit superior shock absorption and vibration absorption capabilities. Zinc alloy die-casting molds have a long service life (averaging over 600000 to 800000 mold cycles) and lower mold opening costs compared to aluminum alloys.

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

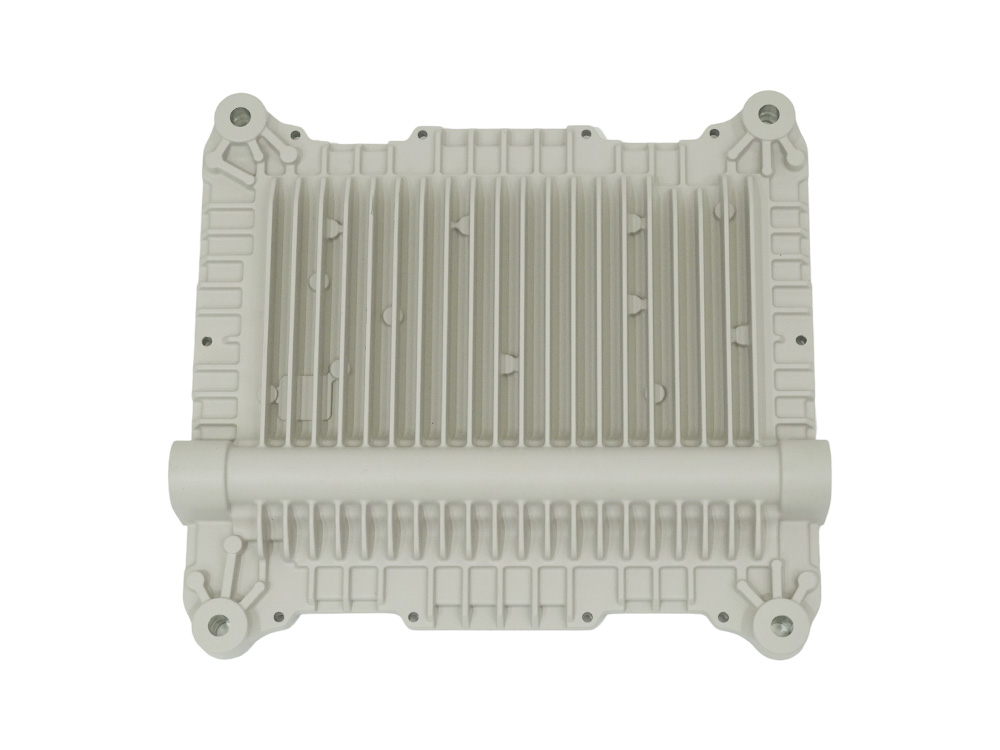

(1) Electronic components and communication equipment (2) Optical and general instruments (3) Automotive parts (4) Commercial machinery (5) Household appliances (6) Industrial machinery (7) General hardware and tools  Among numerous die-casting alloys, aluminum die-casting parts are lightweight and can withstand high operating temperatures. Aluminum die castings have high strength and rigidity, as well as good corrosion resistance and heat dissipation ability, making them ideal products for use in harsh environments. The lifespan of zinc alloy die-casting molds is short (averaging around 50000 to 80000 mold cycles) and the cost of mold opening is higher than that of zinc alloy.

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(1) Electronic appliances (4) National defense industry (2) Machinery and equipment (5) Building construction (3) Transportation (6) Household and other appliances |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Message successfully sent